| Item | YZYX120 | YZYX120J | YZYX120SL |

| Processing Capacity(t/24h) | 6.5 | 7 | 7 |

| Oil Content of Dry Ckes(%) | ≤7.0 | ≤6.0 | ≤6.0 |

| Motor Power(kw) | 11 or 15 | 11 or 15 | 11 05 15 |

| Weight(kg) | 680 | 718 | 808 |

| Measurment(L*W*H)(mm) | 1860*622*1275 | 2110*780*1350 | 2150*1100*1350 |

| Spiral axes rotate(r/min) | 32-40 | 37-45 | 37-45 |

.png)

The series YZYX120 spiral oil press produced by our company is suitable for squeezing vegetable oil from rapeseed, cottonseed, soybean, shelled peanut, flax seed, tung oil seed, sunflower seed and palm kernel, etc. The product has characteristics of small investment, high capacity, strong compatibility and high efficiency. It is widely used in small oil refinery and rural enterprise.

YZYX120 is the basic 2-step-squeezing spiral oil press. YZYX120-8 is 3-step-squeezing spiral oil press, which has larger press chest cavity, suitable for the users who have operating experience and stress on the oil content of dry cakes. YZYX120-9 is 4-step-squeezing spiral oil press with lengthened press chest.

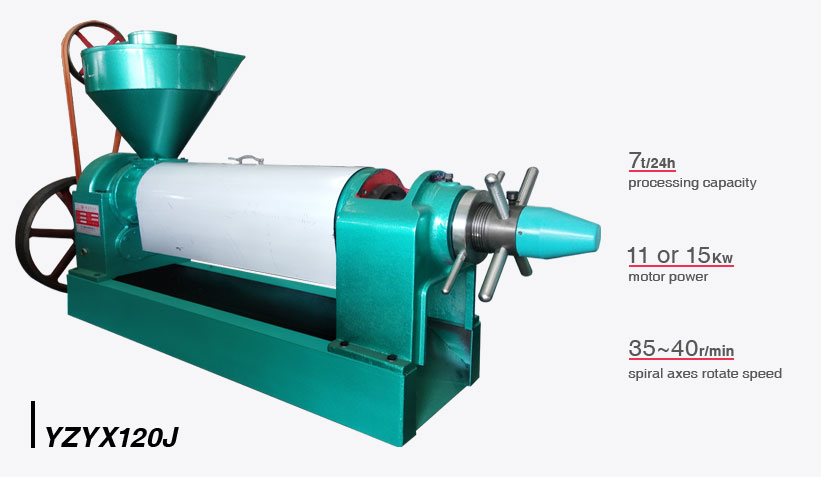

The model YZYX120J is a 4 step squeezing spiral oil press. The squeezing force is bigger; the oil plants can be squeezed in the chamber for a longer time. In the meanwhile, without increasing the electric power, the day capacity is bigger, the oil yield efficiency is higher, the oil rate in the cake is lower (5.5% is the best value). This series of machine save energy consumption, save land source and energy, increase social benefit, meet the market demand and have a big market.

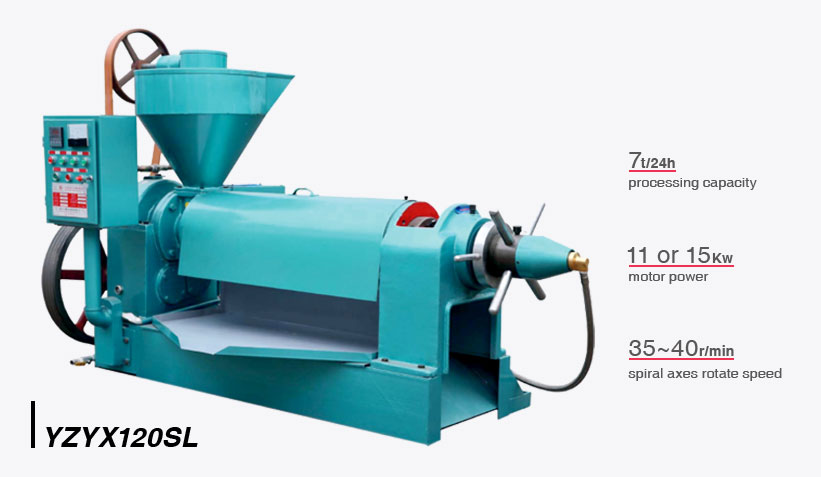

The model YZYX120SL is new 4-step squeezing oil press machine, with water cooling system to prevent the temperature in the squeeze chamber going too high, preserve the nutrition substances in the oil. The processing capcity and oil yield is higher without increasing power consumption. The press chamber’ force can be maintained stable (between 120℃ to 140℃ according to different oil plants’ requests), avoiding the protein change too much than needed and the oil plants get burnt as the temperature getting too high after long term and continuous squeezing. Consequently, the oil yield efficiency can be increased and the vitamin, fat acids, mineral and other nutrients get lost. At the same time, it increases the value of the cake, automation. The structure is compact, the operation and maintenance is easy. This model has obtained national patent (patent number ZL201020677033.7).

Below features are based on oil plants above the average quality smoothly and continuously squeezed after such pretreatments as screening, husking, flaking and cooking, etc.

| Oil Plants | Processing Capacity |

Oil content of Dry cakes (%) | Oil Yield Efficiency (t/24h) | Electricity Consumption (kw.h/t) |

| Rapeseed | ≥6.5 | ≤7.4 | ≥84 | ≤34 |

| Cotton seeds | ≥6.5 | ≤6.3 | ≥80 | ≤54 |

| Soybean | ≥5.5 | ≤6.2 | ≥69 | ≤51 |

| Peanut | ≥6.5 | ≤6.3 | ≤92.5 | ≤34 |

① It is normal that sometimes the actual results may be a little different from those in the index because the oil plant’s type, quality and original content may be different in different areas.

② The day capacity (t/24h) is based on using hot way to squeeze one time. The more the squeeze times are, the lower the date capacity is.

The sufficiently high temperature in the press chest is significant for the output and the oil yield efficiency. Normal pressure can’t be formed for the oil plants, cake can’t be formed and the oil yield efficiency will be affected when it is too high or too low. In order to make the squeeze chamber have the best temperature, shorten the preparation time, there are two electric heating tubes with 0.75k between the top and bottom press cage. In the meanwhile, to avoid the temperature of the press chamber getting too high, the machine is added with water cooling system, when the button switch is in automatic model, the oil press starts to warm up the press chamber by squeezing cake, in the meantime, the two electric tubes started to heat the press chamber, when the heating indication light is on. When the temperature reaches the regulated degree, the heating indication light will be off.

we will contact you within 24 hours.

WhatsAPP

WhatsAPP