Main equipment parameters of GLY500 Oil Refinery Machine

|

No.

|

Parts Name

|

Specification or Model No.

|

Power consumption(kW)

|

|

1

|

Refining tank

|

DN700*1300

|

12/0.55

|

|

2

|

Vacuum dehydration tank

|

DN650*1290

|

12

|

|

3

|

Vacuum buffer tank

|

DN300*500

|

/

|

|

4

|

Decoloration tank

|

DN650*1100

|

/

|

|

5

|

Water circling vacuum pump

|

2BV2061

|

1.5

|

|

6

|

Oil Pump

|

/

|

0.18~0.37

|

|

Overall Measurement:2*(1920×900×2140)(mm)

|

Each equipment functions of GLY500 Oil Refinery Machine

1 Refining tank: degumming by hydration method, deacidification by Alkali neutralization method.

2 Vacuum dehydration tank: drying and dehydration.

3 Water circling vacuum pump: create a vacuum when doing drying & dehydration process.

4 Decoloration tank: filter and decolor the oil. Make oil product clear and transparent, and reduce oil color.

5 Metering tank: metering and heating of the water, salt water, and Alkali liquid.

6 Alkali mixing tank: mix and dissolve solid Alkali with water. Make neutral Alkali liquid with required density.

Processing Capacity of GLY500 Oil Refinery Machine

GLY500 capacity introduction: daily capacity 500-2000kg

The refining equipment processing capacity is related to the oil refining process and the oil grade. The refining tank processing cycle is related to the raw oil quality and the finished oil grade requirements.

Refining tank processing capacity 200-250L/tank, dehydration tank, and refining tank are matched, decolorization tank filtration capacity 300L/tank, with time about 4-5 hours.

(1) If the crude oil quality is good, after heating, hydration, sedimentation, dehydration and other processes, it takes about 4 hours to deal with one tank.

(2) If the crude oil quality is bad and the finished oil grade needs high requirement, after heating, hydration, sedimentation, alkali refining, washing, dehydration and other processes, it takes about 12-24 hours for processing one tank.

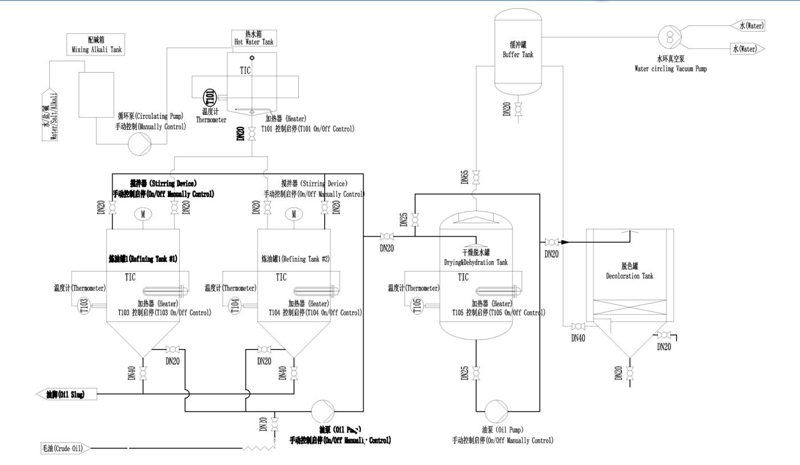

Sketch of refining procedures

WhatsAPP

WhatsAPP