Centrifugal Oil Filter has the models as below:

|

Model

|

YLSC430

|

YLSC500

|

YLW 150

|

|

Picture

|

|

|

|

|

Processing capacity(kg/h)

|

80-120

|

120-180

|

240-340

|

|

Revolving speed of rotor drum (r/min)

|

1460

|

1246

|

4015

|

|

Main electromotor power(kW)

|

4

|

4

|

3.24

|

|

The diameter of the rotor drum (mm)

|

430

|

500

|

150

|

|

Measurement (mm)

|

580x520x930

|

840x660x900

|

1060x610x960

|

|

Weight(kg)

|

180

|

217

|

237

|

The YLSC430 and YLSC500 Centrifugal Oil Filter by Guangxin can be matched with our series of oil press machines of YZYX95, YZXY10, YZYX120, and YZYX130, for filtering various crude oil, achieves precise filter result, compared with traditional oil filters.

The precise centrifugal oil filter YLW150 is composed of the rack, centrifuge system, electrical system, transmission, lubrication system, and other components.

|

Model

|

YLSCSH500

|

|

Picture

|

|

|

Processing capacity(kg/h)

|

300-400

|

|

Oil gear pump power(kW)

|

0.55

|

|

Main electromotor power(kW)

|

4

|

|

Heating tube power(kW)

|

2

|

|

The diameter of the rotor drum (mm)

|

500

|

|

The diameter of the hydration cylinder (mm)

|

460

|

|

Measurement (mm)

|

1310x560x860

|

|

Weight(kg)

|

260

|

YSLCSH500 multi-functional centrifugal oil filter is used for processing hydration and filtration to the crude oil, separating oil from dregs. Comparing with single centrifugal oil filter, this oil filter has below advantages:

1 Has a cylinder especially for the hydration process;

2 Has an electric control box, easy operation;

3 Has electric heater, can heat crude oil or maintain temperature so as to ensure hydration result;

4 Has time-delay switch, automatically stop when filtration is finished. And the length of working time can be set and is adjustable;

5 Automatically stir the oil during the hydration process, easy operation and labor saving.

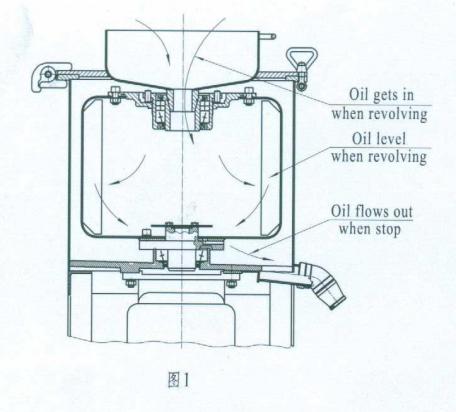

After Hydration in the hydration tank, the crude oil to be transferred into the high-speed rotating drum by the oil pump, the residual and oil adsorb on the inwall of the drum due to powerful centrifugal force. Because the residual is heavier than the oil, it has more centrifugal force obtained and clings at the closer inwall, thereby there is clean oil obtained on the surface. Then the clean oil outflows from the outlet and the residual are pushed out by the vane on the spiral to achieve separation.

WhatsAPP

WhatsAPP